From Concept to Reality: Streamlining Production with Rapid Prototyping

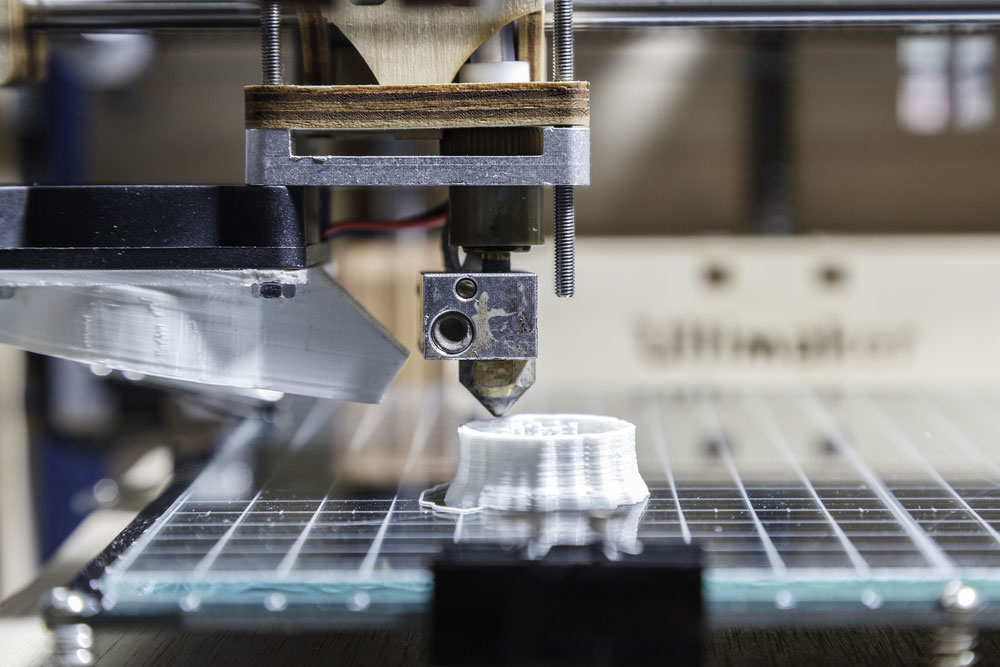

Rapid prototyping is a powerful innovation that has transformed the way products are made. It allows engineers and designers to turn their ideas into physical models at an unprecedented speed. This technology has played a pivotal role in streamlining the production process by reducing the time and cost required to create a prototype. With advanced CAD software and 3D printing technology, designers can quickly create a prototype that accurately represents their conceptualization.

Rapid prototyping has drastically reduced the time required to develop a new product. Traditionally, the process of developing a product involved several rounds of designing, analyzing, prototyping, and testing one after the other, costing a lot of time and money. Each round depended on the production of a new prototype based on the previous round’s result, which took a long time to develop. Rapid prototyping has simplified this process, allowing designers to rapidly create enhanced versions of the prototypes. This allows designers to quickly test, optimize, and approve the design before moving to the production phase.

Additionally, rapid prototyping has also helped with product customization. The technology allows for the production of an endless variety of products precisely as required, tailored to the customer’s needs. With the right software and equipment, designers can produce a quick and perfect prototype to meet the desired shape, size, and specifications of the customer’s design. This level of customization is only possible with rapid prototyping technology, which allows for intricate and unique designs to be produced.

Furthermore, rapid prototyping has enabled designers to identify and solve potential problems early on in the production process. It has created a more systematic and efficient way of identifying design flaws, missing components, and faulty structures. This allows designers to analyze and fix the flaws in a timely and cost-effective manner, avoiding lengthy redesigns that hold up the production process. The technology also allows for quick exploration of numerous design options to establish the most efficient and cost-effective design.

In conclusion, Rapid prototyping has revolutionized the way products are produced by increasing production speed, reducing costs, and improving the quality of products. It has transformed every stage of the production process, allowing engineers and designers to produce prototypes that are precise, customizable, and easy to optimize. The increasing popularity of rapid prototyping technology has enabled companies to stay competitive by quickly developing products that meet their customer’s constantly changing needs. It has made it possible for manufacturers to rapidly and efficiently create innovative and beautiful products, significantly reducing their chances of failure, saving them time, cost, and significantly increasing their profits. As technology continues to advance, rapid prototyping will undoubtedly play a crucial role in transforming the production industry further.